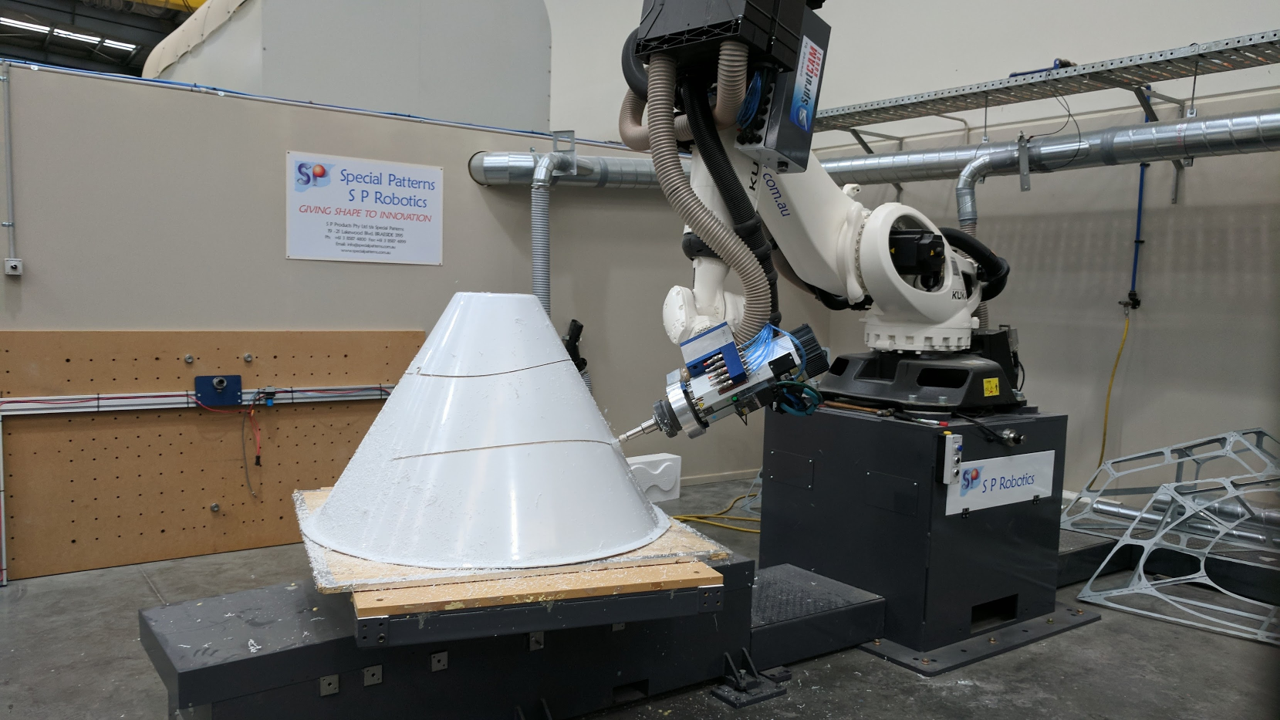

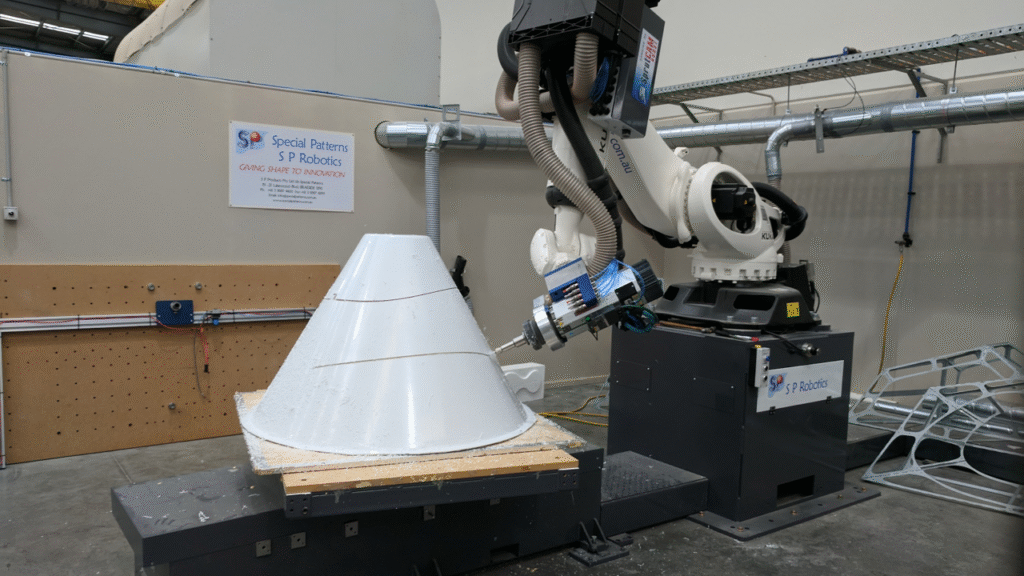

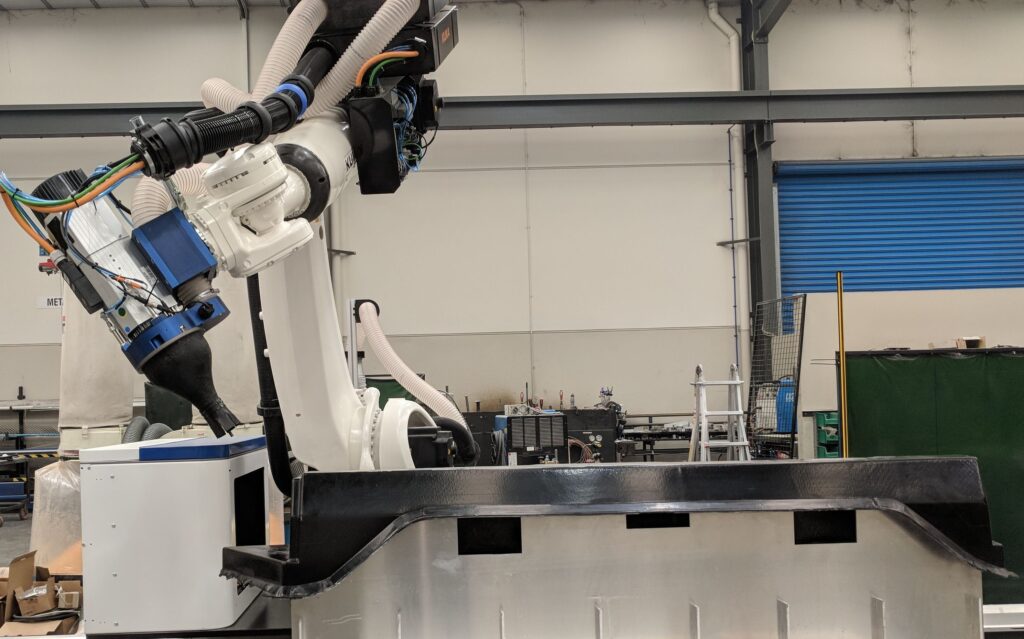

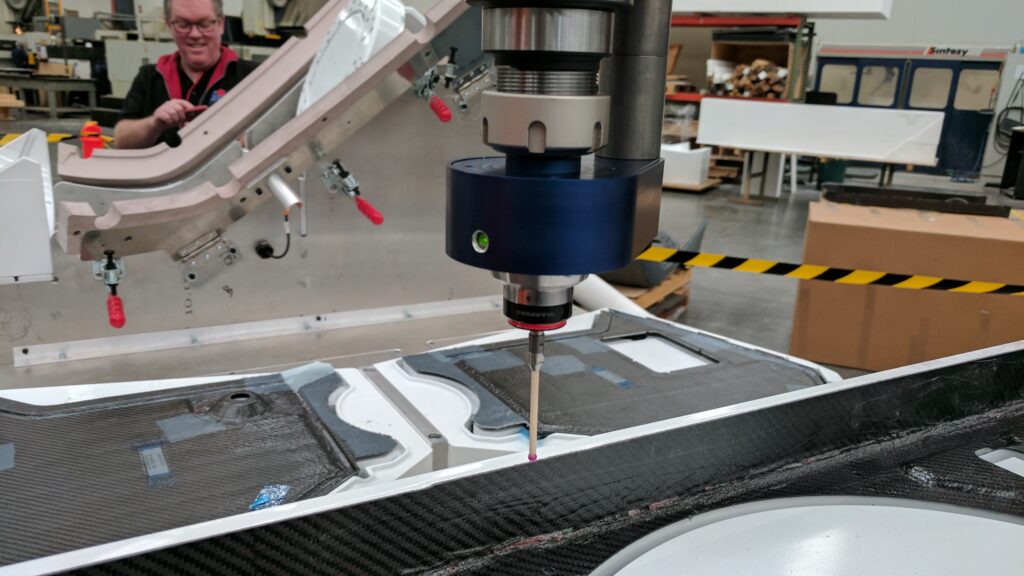

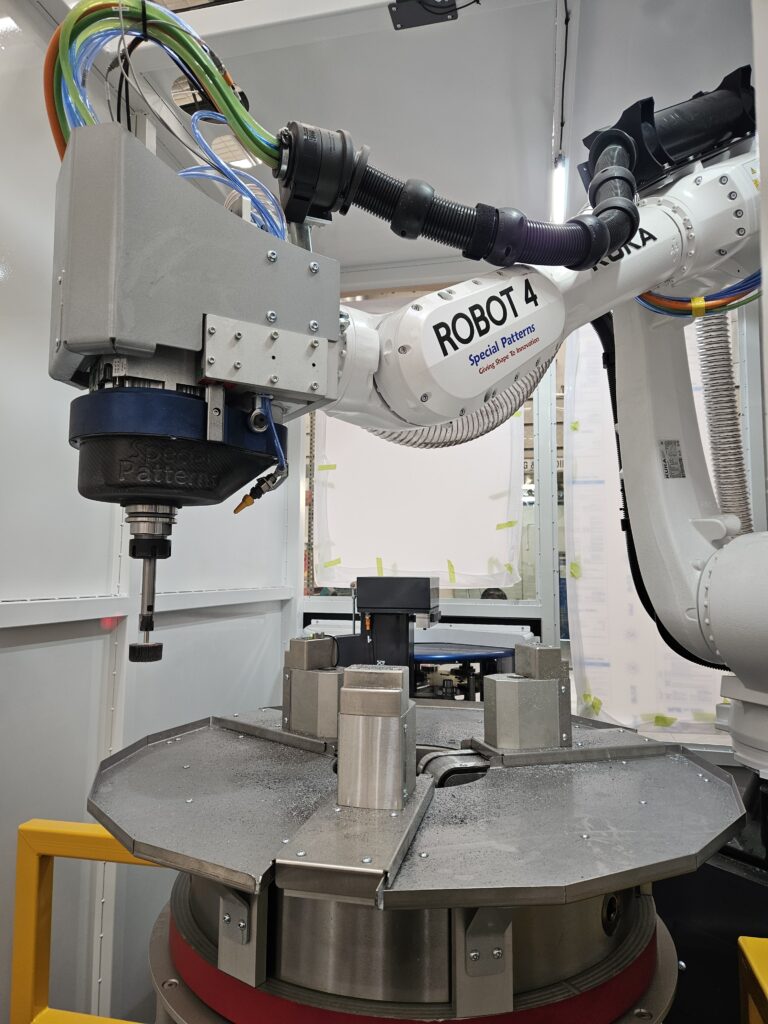

We build Robotic Part Trimming Systems for all materials

Robotic trimming is faster then a 5 axis CNC and more affordable.

Cost and Return on Investment (ROI)

-

Lower Upfront Cost: A complete 7-axis articulated robot system generally has a significantly lower initial capital investment compared to a rigid, dedicated 5-axis CNC machining center with a similar working envelope. This can lead to a faster ROI (Return on Investment).

-

Reduced Fixturing Costs: Because the robot arm has a greater and more flexible range of motion (often 7 or more axes vs. the 5 axes of the CNC machine), it can reach more complex features and angles on the part in a single setup. This can reduce the need for expensive, complex, custom fixtures that are often required for a 5-axis CNC.

Flexibility and Versatility

-

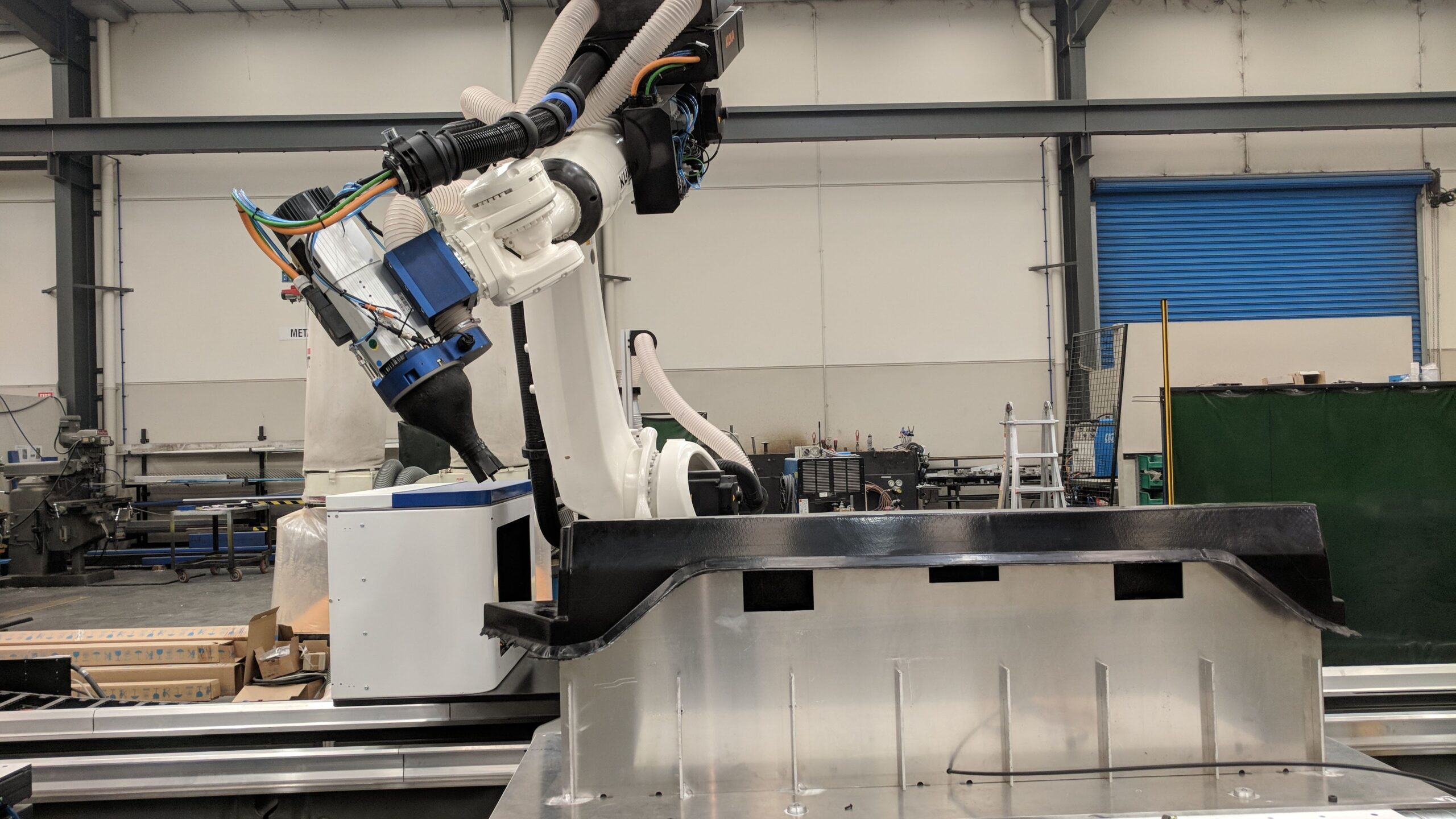

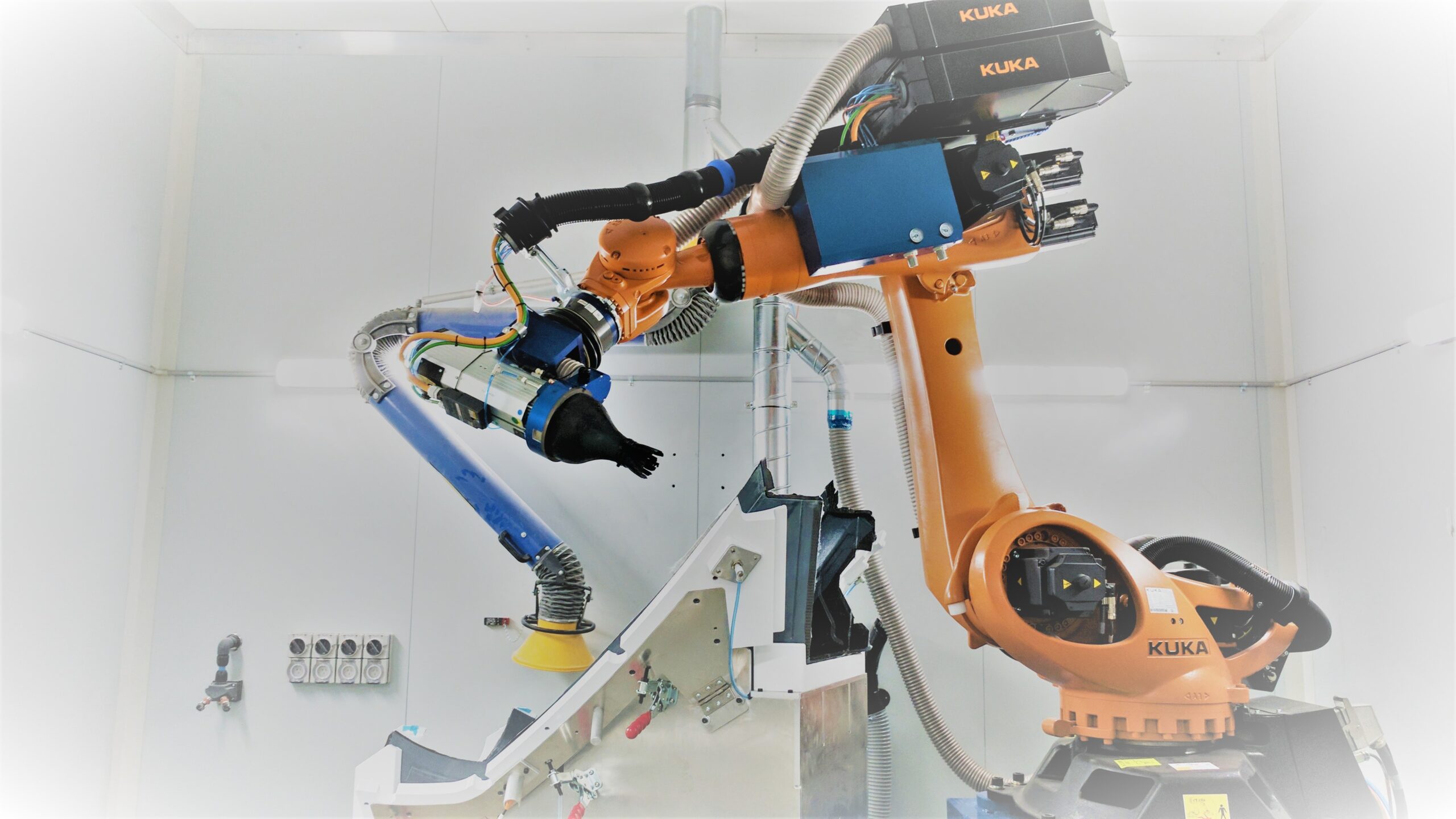

Higher Degrees of Freedom (DOF): Robotic arms typically offer six degrees of freedom (6-axis), and sometimes seven, providing superior reach and maneuverability around complex part geometries. A 5-axis CNC machine has a fixed workspace defined by its gantry system.

-

The robot can often reach areas of a complex part, such as undercuts or features on the underside, in one setup, eliminating the need to physically re-fixture and re-program the part.

-

-

Scalability and Part Size: Robots can process a much larger range of part sizes for a given footprint. By placing the robot on a track (or rail), its working envelope becomes massive, allowing it to trim parts far larger than the fixed table size of a 5-axis CNC router.

-

Redeployment and Tool Change: Robots are inherently more flexible and can be easily reprogrammed and re-tooled for different tasks (e.g., switching from trimming to drilling, sanding, or handling). If the production need for the trimming cell ends, the robot can be re-deployed to another function entirely, protecting the initial investment.

Workspace and Integration

-

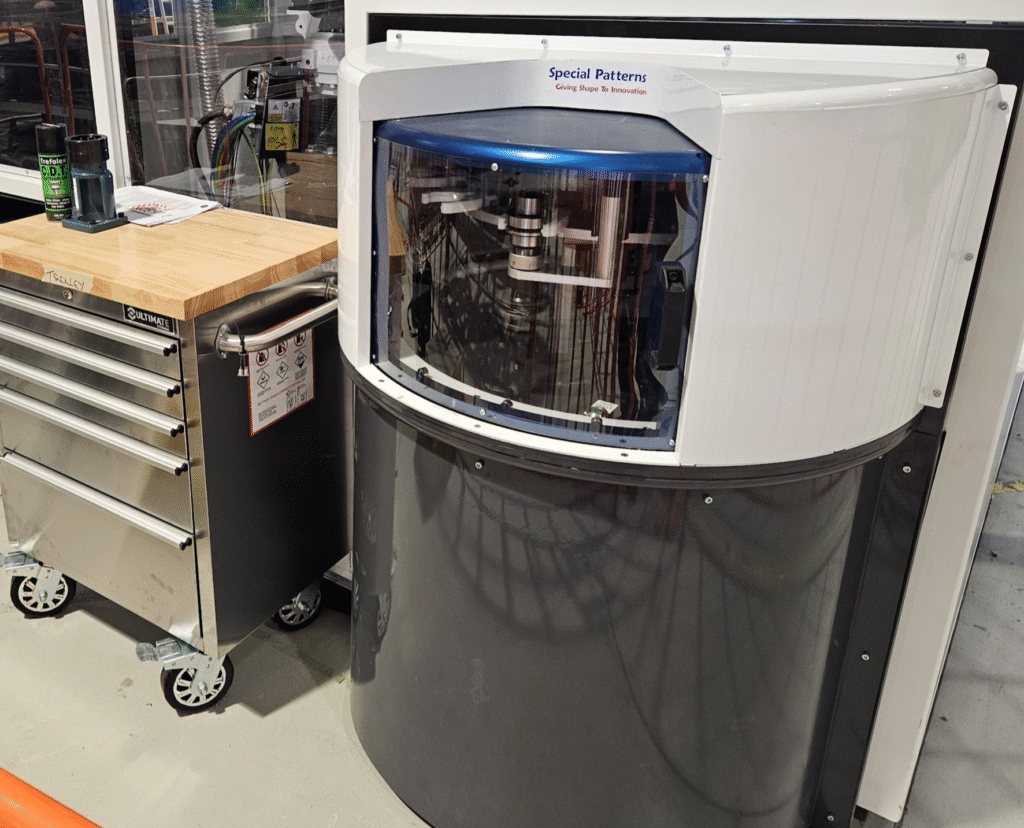

Smaller Footprint/Workspace: A robot cell can often be more compact than a large gantry-style 5-axis CNC machine with a fixed bed, leading to better space utilization on the factory floor.

-

Integrated Automation: The robot's flexibility allows it to perform more than just trimming. It can be programmed to load and unload parts from a fixture, perform a trimming operation, and then move the finished part to the next station, enabling a fully automated cell without human intervention.

-

Alternative Tooling: Robotic arms can readily accommodate different end-effectors, such as a router spindle, waterjet nozzle, laser cutter, or ultrasonic knife, offering greater process versatility within a single cell.