From concept to tooling, Special Patterns meets and exceeds the industry requirements

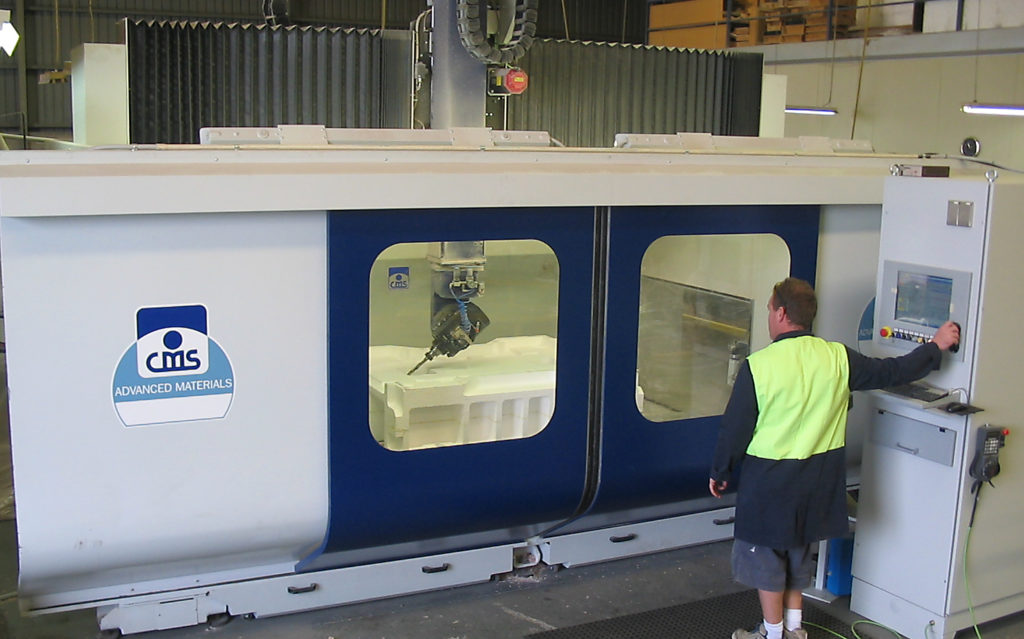

Here at Special Patterns we now have seven CNC machining centres. In November 2013 we took delivery of our third and largest 5-axis machine. Our machines are capable of machining a large array of materials.

Powerful CAD/CAM workstations are used to run SprutCAM, Catia and Machining Strategist software to perform all of our surfacing, design, drawing and cutter path needs.

Our CNC machining centres are directly linked with our network of computers to download a variety of cutterpaths produced in house including roughing, pocket milling, 2D/3D surface milling, 2D/3D profiling, drilling, tapping and scribing.

For verification inspection reports and reverse engineering we use Power Inspect combined with our Faro Arm.